FMS flexible manufacturing system will become the core competence of manufacturing industry

In the future, China, the outward migration of labor-intensive industries that win with mass production and low cost to Southeast Asia is unstoppable, and the only thing that China can leave behind is small-volume, customized, flexible manufacturing capacity. To put this statement in another way, if China can massively transform its production and manufacturing systems so that they all have flexible production capacity, then more manufacturing can be left in China.

Flexible manufacturing means that the production line can be switched at will between high-volume and low-volume production under the condition that quality, delivery and cost remain consistent.

Flexible manufacturing system (FMS) has highly flexible and automated processing capability, which adapts to the requirements of rapid product changes and is the new direction of smart factory construction.

Flexible manufacturing system (FMS) means that the central control computer is equipped with multi-channel protocol control management software, which is compatible with ERP, MES and other enterprise management software, as well as with various machine tool equipment hardware control systems such as Siemens, Fanuc, Mitsubishi and other industrial control systems to achieve cross-platform information control communication and sharing; equipped with RGV or AGV to achieve logistics management; and can realize all the system's The manufacturing system with material flow or information flow automation can be called a flexible automation production line, with the main features: process concentration, no fixed production schedule, and non-sequential transport of logistics. Widely used in aerospace, engineering machinery, mechanical equipment manufacturing, diesel engines, new energy vehicles and other industries multi-species, small batch production scenarios; characterized by process integration, unmanned black light production, process procedures complex manufacturing.

According to the scale, flexibility and other characteristics of the manufacturing system, flexible automation has a variety of forms, FMS flexible manufacturing system (hereinafter referred to as: FMS) is one of them; in addition, it also contains independent manufacturing island (AMI), flexible manufacturing cell (FMC), flexible manufacturing workshop and automated factory, etc.

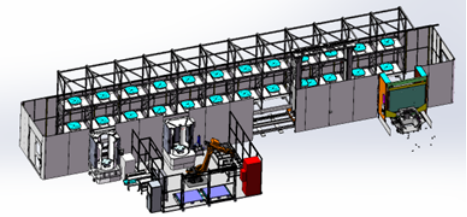

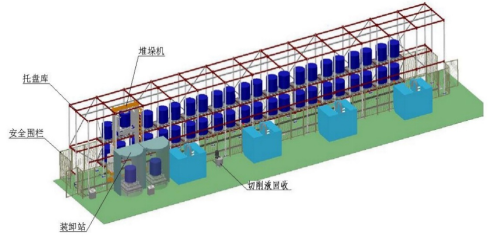

FMS definition: a number of devices linked by a transfer system, the transfer device places the workpiece on other linkage devices to each processing equipment, so that the workpiece processing is accurate, rapid and automated. A central computer controls the machine tool and the transfer system, and the flexible manufacturing system can sometimes process several different parts at the same time. This means that the FMS system can accommodate a variety of processing types, such as machining, sheet metal processing, laser processing, painting processing, etc. For example, the machining FMS includes several machining centers, robotic deburring units, cleaning units, rail conveyors and other equipment and control software, equipped with three-dimensional shelves to place workpieces and tooling, allowing fully automated processing from rough to finish.

FMS composition structure

FMS is a flexible, automated production line system that is a best practice means of effectively increasing a company's business potential in today's demanding survival environment.

The FMS has three main features as follows.

Flexibility Change the type of parts produced according to the actual situation, while multiple parts can be produced at the same time, and production tasks can be adjusted according to current orders or task emergencies.

Efficient The workpiece is manually pre-clamped at the loading gate, saving equipment clamping wait times and fixture change times, and greatly increasing equipment utilization.

Smart With the combination of production planning and IoT, the FMS can provide you with an unattended lights-out production mode.

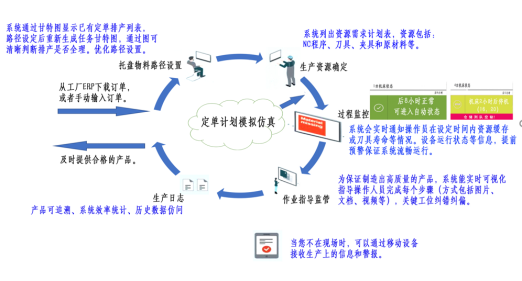

FMS Process

Informatization

Flexible Manufacturing System Features and Benefits

FMS is an automated manufacturing system with a high degree of flexibility, which has the following main advantages.

1. fast strain capability for processing objects. fms has the inherent flexibility to adapt to changes that occur due to changes in market demand and engineering design for multi-species production. And it can also insert spare parts and urgent parts manufacturing tasks without significantly disrupting the normal production schedule.

2, to ensure that the system has a certain degree of flexibility at the same time, but also has a high utilization rate of equipment. fms can obtain high efficiency, one is the control system to each processing object are arranged for processing machine tools, once the machine tool is free, immediately send the parts on the processing, while the corresponding CNC machining program into this machine. Second, because the parts sent to the machine tool have already been loaded on the loading station on the pallet, so the machine does not need to wait for the parts to be loaded.

3, reduce the amount of work in process, shortening the production lead time. Compared to general machining, FMS has an amazing effect on reducing the number of parts in the process due to the reduced waiting time. The main factors contributing to the shortening of the waiting time are: the system occupies a small space; the work-in-process flow route is shortened; the processing process is concentrated, reducing the number of times the parts are clamped; and the computer efficiently feeds the parts into the FMS in batches according to the established schedule.

4, high product quality, good stability. fms compared with the joint system of CNC machine tools, product quality is high, and has good quality stability. The high degree of automation, the reduction of the number of times the parts are loaded, the careful preparation of the tooling, etc. are conducive to improving the quality of individual parts.

5、Maintain high production capacity. Many FMS systems are designed to have when one or more machine tool failure can still downgrade the ability to run. That is, the use of processing capacity redundancy design, and make the material transfer system has the ability to bypass the failed machine. At this point, although the productivity to reduce some, but the system can still maintain production.

6、Reduce equipment investment. Due to high equipment utilization, FMS can complete the same amount of work with less equipment. The shop uses multiple machining centers for flexible manufacturing systems, the investment can generally be reduced by two-thirds.

7, reduce the cost of direct labor hours. CNC machine tools are working under computer control, the entire system in addition to workpiece loading and unloading, no workers to manipulate.

According to the development situation of the Chinese market, the future market demand for products will be personalized, both in terms of production implementation and manufacturing needs, to promote the implementation of FMS are in line with the general trend of the development of personalized demand. fms system in processing flexibility has significantly improved, it has a variety of processing methods, especially adapted to the type of multi-species small batch production. The production of machining companies is very suitable for FMS, which achieves a high degree of automation of machining processes and material transportation.

The trend of flexible manufacturing system

A higher degree of integration Through the integration and integration of advanced manufacturing technology, information technology and intelligent technology, etc. to achieve equipment integration, tool integration, tooling integration, testing integration, logistics integration, information network integration, workshop management integration.

The scope of application is gradually expanding, such as metal cutting flexible manufacturing system is gradually expanding the scope of batch adaptation and variety of adaptation, on the other hand, the flexible manufacturing system from the initial metal cutting processing to metal hot processing, assembly and the entire range of machinery manufacturing development, and rapid penetration to the electronics, food, pharmaceutical, chemical and other industries.

To "self-regulated decentralized" development of self-regulated decentralized units constitute the FMS system by each independent and equal flexible manufacturing units (FMC), completely different from the past FMS system, can be combined with the market and the actual production needs, through the self-supporting decentralized units to expand manufacturing flexibility. According to the market and product changes, the machine tool and peripheral equipment can be flexibly combined to adapt to the production needs of the product.

Single technical performance and system performance continue to improve For example, the use of a variety of new technologies to improve machine tool processing accuracy, processing efficiency; comprehensive use of advanced detection means, networks, databases and artificial intelligence technology to improve the flexible manufacturing system units and systems self-diagnosis, self-error, self-accumulation, self-learning capabilities; the use of advanced control methods and computer platform technology to realize the self-coordination, self-reorganization and early warning function of the flexible manufacturing system, etc.